gas injectionModify Date : 2020-08-03 10:40:09

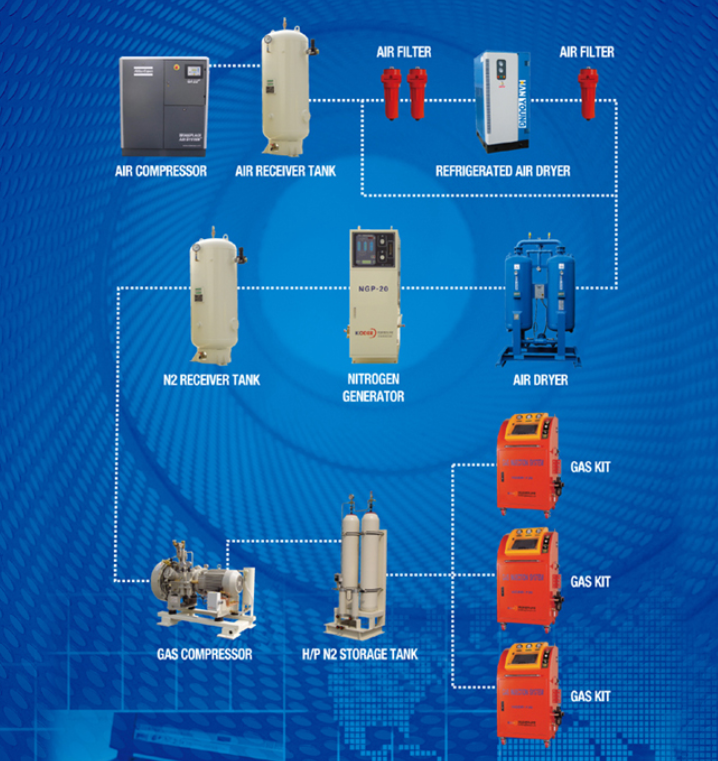

Gas Injection System Layout

gas controller

What is gas forming?

Gas formation is a new concept of injection molding method that overcomes contraction, wheel, and process time, which are vulnerable to general injection, by injecting high-pressure gas after filling a certain amount of resin by injection machine.

the advantages of gas formation of gas

Cost reduction aspects:

Reduced resin materials:reduces weight of the resin, enabling integral forming, reducing the number of parts

Reduced process time:Cycle time reduction,reduced cooling time due to reduced thickness

Reducing the cost of the balance due to the majority of the balance of payments

Reducing the cost of making molds

Quality aspects:

Reduced bending defect due to uniform prostatic pressure

Reduced shrinkage defect due to pressure from filling of gas

strength reinforcement by gas channel

sinkmark reduction

design aspect

Design degrees of freedom: freedom of thickness, increased freedom of curvature

Minimize distortion

hollow design:reducing component scores,Stiffening of the hollow structure of the post-process.

Extruded gogwangtaek

Characteristics

Rapid Heating, cooling mold by using the hot steam.

Be in conformity with the highly polished production.

The compact and slim design, installation will be easy.

Electricity cost savings by minimizing heat loss can do.

degassing

For mold vacuum system purposes:

Improve quality, shorten cycle time, reduce mold costs, and enable thin product formation

Advantages of a gas vacuum system include:

cost-cutting aspects, quality aspects, design aspects

본 사이트는

Internet Explorer 8 이하 버전을

지원하지 않습니다.

Internet Explorer 9 이상으로 업데이트 하거나

크롬, 파이어폭스, 오페라, 사파리 최신 브라우저를 이용해 주십시오.

불편을 드려 죄송합니다.