screw coatingModify Date : 2020-07-31 13:13:30

01SCREW Coating Overview

PVD coating, which contributes greatly to SCREW performance improvement, is thin film but has excellent effect in reducing strong surface hardness, friction, and wear.

02SCREW Illumination

Along with screw design, it is the most important factor in determining quality. The luminance of the screw affects the molding (supply and resin flow). Poor surface illumination reduces the fluidity of the resin, resulting in retention GASs and carbides. Before and after heat treatment, it was common to apply buffing and chromium plating. Currently, various coating methods are used to form high quality luminance.It is important to note that the surface illumination before coating must be kept below Ra -0.2 in order to obtain quality coating products.

resin containing grinding agent

resin containing more than 40% GF

excellent abrasion condition

Unique Color Gray Violet

Thin Film Hardness (HV3300) 0.025

Thin film thickness (μm) 1.5 to 1.0

Thermal Safety 900°C

Applied GF-containing materials (PA, PBT)

fluorine and chlorine-containing resin

resin containing copper active components

excellent corrosion protection

Unique Color Silver

Thin Film Hardness (HV1750) 0.025

Thin film thickness (μm) 1.5 to 1.0

Thermal Safety 700°C

Application field optical lens and Teflon series

superior liquidity

Reduced weld formation

Improvement of Deformity and Prevention of Wear

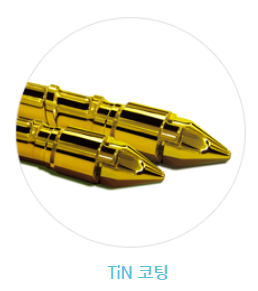

Unique Color Gold

Thin Film Hardness (HV2300) 0.025

Thin film thickness (μm) 1.5 to 1.0

Thermal Safety 595°C

Application field optical lens and light guide plate, keypad

(PC, PMMA)

본 사이트는

Internet Explorer 8 이하 버전을

지원하지 않습니다.

Internet Explorer 9 이상으로 업데이트 하거나

크롬, 파이어폭스, 오페라, 사파리 최신 브라우저를 이용해 주십시오.

불편을 드려 죄송합니다.