Auto Coating TesterModify Date : 2018-11-13 10:59:05

▣ Automatic coating tester

※ Product Information

- By applying PID auto-tuning function, accurate temperature control is possible.

- Forced circulation system for quick drying and uniform temperature distribution

-Improved reproducibility by applying sensor system for zero setting of coated knife.

- The coated knife consists of Doctor knife (0.5mm, 1.0mm, 2.0mm) and Comma knife, and the user can select the required knife.

- The exhaust gas system is applied to the upper part to exhaust the gas inside.

- The drive system is automatic for user convenience.

- Coater moves at uniform speed to realize standardized coating quality

- It is possible to precisely coat up to 0.01mm (10㎛) in cross section on fabric.

- Adjustable coating knife angle, coating thickness, speed and distance.

·coating machine of economic cost

·Coating knife with Doctor Knife (0.5mm, 1.0mm, 2.0mm)

A knife that consists of Comma Knife and that you need.

Available by choice.

·Coat the fabric up to 0.01mm (10μm) in cross-section.

·You can adjust the angle and coating thickness of the coating knife.

·It is easy to coat in a small space.

Model

|

DL-2015MC

|

| Specimen size | 330mm × 430mm |

| Working surface size | 280 × 330mm |

| Coating frame | Pin type |

| Coating speed | Manual |

| Coating head | 1 set(Thickness gauge) |

| Coating knife | Doctor knife, Comma knife (Option) |

| Dimension (Approx.) | 605(W) × 625(D) × 370(H)mm |

It is easy to change according to the method.

·Uniform coating is possible using spray nozzle of Mist type.

·Glass bottle 2l container used and spray drug coagulation or

A magnetic strainer device is installed to prevent sedimentation.

·2l container for cleaning nozzles after spray coating

It can be cleaned cleanly with water or cleaning agent.

·Coating head devices allow height, angle, and thickness control

It is designed and can be adjusted to nine different angles.

·Coating knife with Doctor Knife (0.5mm, 1.0mm, 2.0mm)

Choose and use the knife that is configured with Comma Knife and required by the user

be possible

·A spray barrier has been installed to prevent spray drugs from scattering outside.

·High performance inverter to maintain precise transport speed

Mounted and precisely controllable at low speed.

Model |

DL-2020 |

| Specimen size | 330mm × 430mm |

| Working surface size | 280 × 330mm |

| Transport speed | 0.2~20m/min. |

| Coating head | 1set(Thickness gauge) |

| Coating knife | Doctor knife, Comma knife (Option) |

| Nozzle | Mist type |

| Spray nozzle pressure | 0.5~2.0kgf/㎠ |

| Transport motor | 90W |

| Power source | 220VAC 50/60Hz single phase |

| Dimension (Approx.) | 750(W) × 1000(D) × 1600(H)mm |

·Applied semi-automatic printing system.

·Easy to adjust the squizy angle.

·Water cleaning is possible by attaching leather fabric to the table.

·Digital thickness gauge allows precise thickness control.

(0.01mm=10μm).

·Printing distance, speed control is possible.

·Two (rubber squids, electromagnet bars) printing works at the same time

Can be used.

Model

|

DL-2015SP

|

| Squeegee repeat | 300mm |

| Squeegee operating breadth | 25~400mm |

| Squeegee speed | 1~8m/min. |

| Rubber Squeegee size | 300mm(With 8(T)mm) |

| Electro Magnetic Power Device | 1~100% |

| Screen plate size | Max. 460(W) × 470(L)mm |

| For./Rev. stop switch | Limit switch |

| Safety device | E.m stop switch |

| Speed controller | Inverter controller |

| Drive motor | 200W. |

| Power source | 220VAC 50/60Hz single phase. |

| Weight (approx.) | 80kg |

| Dimension (Approx.) | 870(W) × 830(D) × 505(H)mm |

It's possible.

·Applying a forced circulation system for rapid drying and uniform temperature distribution.

·You can also use it as a coating machine.(Coating Device Option)

·Physical engineering design; compact design.

·Changes in the tissue and color of samples due to heat treatment in the Tenter

It can be prevented from being reworked by measuring it in advance.

·Applying exhaust system to the upper part of the system, the internal emission system

It is designed to force the gas out.

·When the time set in Timer is completed, the pin frame automatically

come out

·Instead of the actuator on the back of the upper cuffer for rapid cooling

It's possible.

·Over temp. limit function to prevent damage to samples due to overheating.

Model

|

DL-2015

|

| Specimen size | 330 × 430mm |

| Working surface size | 280 × 330mm |

| Dry time | 1sec.~99min. (User setting) |

| Circulation fan spped | 700~2500r/min |

| Circulation fan motor | 750W |

| Heater | 7200W(10.5Kw-Option) |

| Temperature range | 20~250℃ |

| Over heat limit | 280℃ |

| Pin frame in/out motor | 200W |

| Power source | 380VAC 50/60Hz 3phase. |

| Dimension (Approx.) | 850(W) × 1200(D) × 1650(H)mm |

It's possible.

·Forced circulation to evenly distribute the temperature inside the chamber

Apply the system.

·The narrow entrance and exit design prevents rapid temperature changes

Can.

·The width of the fabric at the entrance and the entire exit can be adjusted differently.

·Applying exhaust system to the upper part of the chamber

It's designed to force the gas out of the way.

There is

·Two nozzles on the upper and lower parts suitable for the characteristics of wind volume and wind speed

To optimize sample fabric quality by mounting

be designed

·Suitable for cotton fabrics,sey fabrics,poly,nylon B/T tests.

·In-place reproducibility by heat treatment under the same conditions as on-site tensor

Can improve.

· Excellent in nonwoven fabric, leather, and thick sample drying

Model

|

DL-2015CS

|

| Working width | 100~400mm |

| Working length | Max. 0.95m |

| Working speed | 0.2~2.5/m/min. |

| Entry | Manual pinning up |

| Exit | Depinning by automatic |

| Temp.-controller | Digital PID type |

| Temp.-range | 20~250℃ |

| Heating capacity | 30Kw (Step adjuster-2 step) |

| Nozzle | 2ea (Up & down) |

| Nozzle air velocity | Approx. 5~12m/sec. |

| Nozzle air direction | Can be adjusted |

| Circulation fan motor | 1.5Kw |

| Power source | 380VAC 50/60Hz 3phase |

| Weight (Approx.) | 900Kg |

| Dimension (Approx.) | 2680(W) × 1000(D) × 1650(H)mm |

| (Control panel) | (800(W) × 580(D) × 1500(H)mm) |

·Designed based on continuous-tenta manufacturing technology, the two nozzle-type heat circulation systems at the top and bottom minimize the temperature deviation inside the chamber.

Lower and uniform wind speed and wind volume distribution prevented tilting and uneven drying during drying.

·PID auto-tuning function allows accurate temperature control.

·The tunnel-type nozzle of the Slot nozzle provides a soft touch of the fabric when drying.

Also, it can be used for processing nonwoven fabric, file paper, and fleece paper.

·It is possible to adjust the thickness of the upper and lower mesh (5mm to 100mm), so after putting it on the web, it is fused and molded into a non-woven shape by heat.

It is possible to produce for testing.

·Multi-level controlled exhaust system maintains proper humidity in the chamber, so that yellow dust can be prevented, especially with bright-colored fabric.

·2 Chamber drying system is suitable for high-quality production as it allows different temperature settings for each chamber.

·The upper and lower cooling systems are installed on the exit side.

·Excellent on-site reproducibility through the same type of heat circulation as on-site Net dryer.

Model

|

DL-2015CN

|

| Working width | 100~600mm |

| Working length | Max. 1.55m |

| Working speed | 0.2~5m/min. |

| Net conveyor | Up/Down adjustment(Thickness-100mm) |

| Temp.-controller | Digital PID type |

| Temp.-range | 20~250℃ |

| Heating capacity | 60Kw(Step adjuster-4 step) |

| Nozzle | 2ea (Up & Down) |

| Nozzle air velocity | Approx. 0~5m/sec. |

| Nozzle air direction | Can be adjusted by each flap each nozzle |

| Conveyor motor | 0.75Kw 3phase |

| Circulation fan motor | 3.0Kw 3phase (0.75Kw × 4ea) |

| Cooling fan motor | 120W 3phase (60W × 2ea) |

| Power source | 380VAC 50/60Hz 3phase |

| Weight (Approx.) | 1200Kg |

| Dimension (Approx.) | 2500(W) × 1100(D) × 1720(H)mm |

| (Control panel) | (800(W) × 590(D) × 1480(H)mm) |

It's possible.

·Applying a forced circulation system for rapid drying and uniform temperature distribution.

·Stimer method using saturated steam is applied.

·Physical engineering design; compact design.

·The main body is equipped with a steam generator, so no construction is required.

·Dry, process, and set temperature range is adjusted from 20°C to 250°C.

It's possible.

·The humidity range can be adjusted from 20 to 100%.

·When the time set in Timer is completed, the pin frame automatically

come out

·E-control experiment is possible (Option)

·Over temp. limit function to prevent damage to samples due to high heat.

Model

|

DL-2015S

|

| Specimen size | 330 × 430mm |

| Working surface size | 280 × 330mm |

| Temperature controller | Digital PID type (Touch panel) |

| Temperature range | 20~250℃ |

| Temperature sensor | Pt 100Ω |

| Moisture regulation | 20~100% |

| Pin frame dwell time | 6s~9999s |

| pin frame in/out | Automatic |

| Circulation fan speed | 700~2300r/min. |

| Pin frame speed | 0.2~5m/min. |

| Heater | 15kw |

| Power source | 380VAC 50/60Hz 3phase |

| Weight (Approx.) | 240kg |

| Dimension (Approx.) | 900(W) 1200(D) 1700(H)mm |

The cylinder is mounted and uniform pick-up rate can be obtained.

·Gravity coating, dyeing processing, etc.

Can be used.

·High performance inverter to maintain precise rotational speed

Mounted and precisely controllable at low speed.

·For the convenience of users, use a precision regulator on the front of the device.

Install and precisely install the desired air pressure through the pressure gauge.

It's adjustable.

·Physical engineering design; compact design.

·For the safety of the user, the anti-trap device and emergency stop are performed.

Switch, equipped with emergency stop safety bar.

Model

|

DL-2005GV

|

| Type | Vertical |

| Roller size | Ø110 × 350mm |

| Roller material | Rubber(15mm) & stainless |

| Roller knife size | Ø30 × 350mm |

| Roller knife material | Rubber or stainless (Option) |

| Roller & roll knife speed | 0~25r/min. (0.5~20m/min.) |

| Roller hardness | 70~90° Shore |

| Air cylinder pressure | 0~7kgf/㎠ |

| Trust cylinder | Diaphragm type |

| Motor | 400W |

| Power source | 220VAC 50/60Hz single phase |

| Dimension (Approx.) | 1050(W) × 680(D) × 1310(H)mm |

·Trust to minimize left, middle, and right roller pressure deviation

The cylinder is mounted and uniform pick-up rate can be obtained.

·To be used in various ways, such as coating processing (pressing) and dyeing processing (dyeing) functions

Can.

·It can be used in parallel with horizontal and vertical methods.

·High performance inverter to maintain precise rotational speed

Mounted and precisely controllable at low speeds.

·For the convenience of users, use a precision regulator on the front of the device.

Install and precisely install the desired air pressure through the pressure gauge.

It's adjustable.

·Energy design in table type, compact design.

·For the safety of the user, the anti-trap device and emergency stop are performed.

Switch, equipped with emergency stop safety bar.

Model

|

DL-2500HV

|

| Type | Horizontal & Vertical |

| Roller size | Ø110 × 350mm |

| Roller material | Rubber(Thickness 15mm) |

| Roller speed | 0~25r/min. (0.5~20m/min.) |

| Roller hardness | 70° Shore |

| Air cylinder pressure | 0~7kgf/㎠ |

| Trust cylinder | Diaphragm type |

| Motor | 400W |

| Power source | 220VAC 50/60Hz single phase |

| Dimension (Approx.) | 1050(W) × 800(D) × 810(H)mm |

To minimize left, middle and right roller pressure deviation, use the thrust cylinder.

Equal pick-up rate can be obtained when mounted.

·Can be used in various ways, such as dyeing processing (dyeing).

·Fitted with high-performance inverters to maintain precise rotational speed

It is precisely controllable at low speed.

·For the convenience of users, a precision regulator is installed on the front of the device.

The desired air pressure can be precisely adjusted through the pressure gauge.

·Physical engineering design; compact design.

·For the safety of the user, the anti-seize device and emergency stop switch,

Emergency stop safety bar is fitted.

Model

|

DL-2500H

|

| Type | Horizontal |

| Roller size | Ø110 × 350mm |

| Roller material | Rubber (Thickness 15mm) |

| Roller speed | 0~25r/min. (0.5~20m/min.) |

| Roller hardness | 70° Shore |

| Air cylinder pressure | 0~7kgf/㎠ |

| Trust cylinder | Diaphragm type |

| Motor | 400W |

| Power source | 220VAC 50/60Hz single phase |

| Dimension (Approx.) | 920(W) × 750(D) × 680(H)mm |

·Trust to minimize left, middle, and right roller pressure deviation

The cylinder is mounted and uniform pick-up rate can be obtained.

·Can be used in various ways, such as dyeing processing (dyeing).

·High performance inverter to maintain precise rotational speed

Mounted and precisely controllable at low speed.

·For the convenience of users, use a precision regulator on the front of the device.

Install and precisely install the desired air pressure through the pressure gauge.

It's adjustable.

·Physical engineering design; compact design.

·For the safety of the user, the anti-trap device and emergency stop are performed.

Switch, equipped with emergency stop safety bar.

Model

|

DL-2500V

|

| Type | Vertical |

| Roller size | Ø110 × 350mm |

| Roller material | Rubber (Thickness 15mm) |

| Roller speed | 0~25r/min. (0.5~20m/min.) |

| Roller hardness | 70° Shore |

| Air cylinder pressure | 0~7kgf/㎠ |

| Trust cylinder | Diaphragm type |

| Motor | 400W |

| Power source | 220VAC 50/60Hz single phase |

| Dimension (Approx.) | 930(W) × 630(D) × 690(H)mm |

·The roller is designed to be replaced for each application and consists of a basic 2-Roll type.

3-Roll type products can also be ordered and produced.

·The surface polishing is excellent by applying heat to the roller and pressing it.

·Digital PID controller allows precise temperature control.

·To maintain precise rotational speed, a high-performance inverter is fitted to ensure precision at low speed.

It's controllable.

·For the convenience of users, a precision regulator and pressure gauge are installed on the front side of the device, and the left side and

The roller pressure on the right is precisely adjustable.

·Guided plates can be installed at the entrance and exit of the workpiece for convenient and safe use.

·For the safety of the user, the hand-tightening device, the emergency stop foot switch, and the input of the workpiece.

The safety bar is fitted.

·Continuous operation is possible, and Unwinder equipment is optional.

No thanks.

Model

|

DWR&D3-600

|

| Top roller size | Ø180 × 300mm |

| Bottom roller size | Ø250 × 300mm |

| Top roller material | Steel |

| Bottom roller material | Cotton, Paper, Polyamide (Option) |

| Roller working width | 250mm |

| Roller speed | 1.5~15m/min. |

| Roller pressure | Max. 200kgf/㎠ |

| Temperature controller | Digital PID type |

| Temperature range | Max. 180℃ |

| Heater | 3600W |

| Drive motor | 1.5kw 3phase |

| Power source | 380VAC 50/60Hz 3phase |

| Weight (Approx.) | 300kg |

| Dimension (Approx.) | 550(W) × 1380(D) × 1510(H)mm |

| (Include winder equipment) | (1500(W) × 1380(D) × 1510(H)mm) |

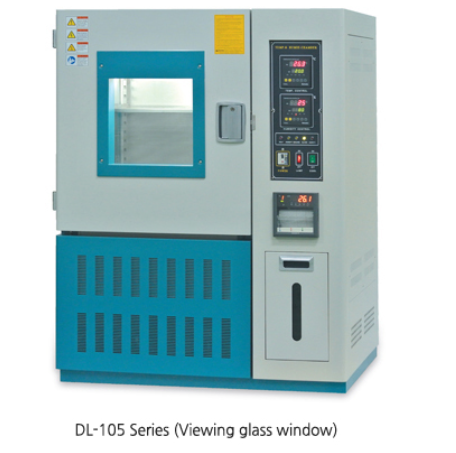

·Microprocessor based PID controller enables accurate temperature control.

(Integrated Auto Tuning)

·Applying a forced circulation system for rapid drying and uniform temperature distribution.

·Internal condition can be checked as a transparent window is installed.

·Applying an air circulation system on the upper and lower parts of the door for safe use at high temperatures.

Can.

·In order to protect users and samples, overheating prevention and overload prevention devices are installed.

·The size can be changed according to the user's experimental conditions (Option)

Model

|

DL-4001S

|

DL-4001M

|

DL-4001L

|

| Chamber capacity | 91 Liter | 150 Liter | 300 Liter |

| Temperature controller | Digital PID controller | ||

| Temperature range | Ambient +5℃ to 150℃ | ||

| Temperature accuracy | ±1℃ at 100℃ | ||

| Temperature sensor | CA type | ||

| Test timer | Digital timer 99hr. 59min. or infinity | ||

| Circulation fan | Sirocco fan motor | ||

| Material(Internal) | Stainless steel(SUS#304) polishing plate | ||

| Material(External) | Steel(SCP-1) with powder coating | ||

| Door | Silicon seal door with window | ||

| Safety device | Hydraulic temperature controller | ||

| Heater | 1200W | 1500W | 2200W |

| Shelves | 2ea | 3ea | 4ea |

| Power source | 220VAC 50 or 60Hz single phase | 220VAC 50 or 60Hz single phase | 220VAC 50 or 60Hz single phase |

| Dimension(Internal) | 450(W) × 450(D) × 450(H)mm | 500(W) × 500(D) × 600(H)mm | 600(W) × 500(D) × 1000(H)mm |

| Dimension(External) | 550(W) × 580(D) × 800(H)mm | 630(W) × 700(D) × 930(H)mm | 790(W) × 700(D) × 1560(H)mm |

·Administrative temperature control using Digital PID controller

It is possible and convenient to use.

·Use an electronic humidity sensor to maintain a stable humidity.

The data is very responsive and durable.

· Reservation function makes it possible to make a reservation and easy to use.

·Stainless steel makes it more durable.

It is easy to adjust the height of the shelf according to the size of the sample.

·Fluence windows are installed in the door, making it easy to check the internal condition.

·For the protection of samples and the safety of equipment, over temperature, overcooling,

Abnormal humidity alarm, automatic water level control, overload blocker, etc.

Safety is fitted.

·Recorder can be attached (Option)

Model

|

DL-105SG

|

DL-105MG

|

DL-105LG

|

| Chamber capacity | 150 Liter | 288 Liter | 700 Liter |

| Temperature controller | Digital PID controller | ||

| Temperature range | -10℃ to 70℃ | ||

| Temperature accuracy | ±0.1℃ at 37℃ | ||

| Humidity controller | Digital PID controller | ||

| Humidity range | 30~95% RH at 35℃ | ||

| Humidity accuracy | ±2% at 20℃ 70% | ||

| Material(Internal) | Stainless steel(SUS#304) polishing plate | ||

| Material(External) | Steel(SCP-1) with powder coating | ||

| Door | Silicon seal door with light glass window | ||

| Safety device | Hydraulic temperature controller | ||

| Heater | 3500W | 4500W | 6000W |

| Shelves | 2ea | 3ea | 4ea |

| Power source | 220VAC 50 or 60Hz single phase | 220VAC 50 or 60Hz single phase | 220VAC 50 or 60Hz single phase |

| Dimension(Internal) | 500(W) × 500(D) × 600(H)mm | 600(W) × 600(D) × 800(H)mm | 1000(W) × 700(D) × 1000(H)mm |

| Dimension(External) | 990(W) × 850(D) × 1310(H)mm | 1000(W) × 880(D) × 1550(H)mm | 1430(W) × 980(D) × 1750(H)mm |

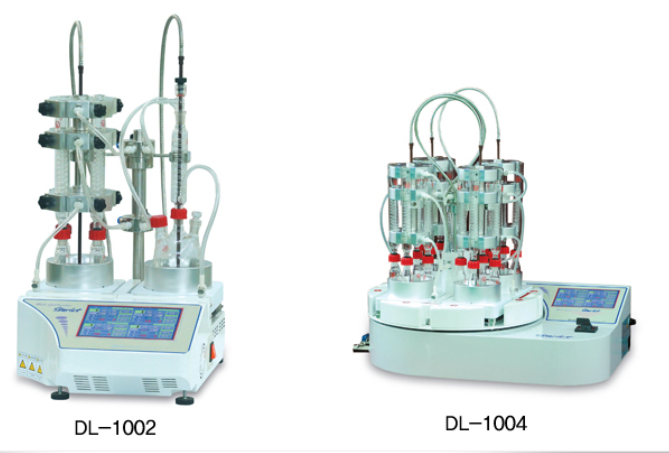

·Independent temperature control allows four or more different experiments to be carried out simultaneously

be designed

·Independent precise temperature control by installing insulation and cooling walls to minimize thermal interference

It's possible.

·The heat section has excellent corrosion resistance due to the treatment of Teflon or Ceramic coating.

·The cooling water circulation piping is installed to prevent evaporation of the solution.

·A built-in gas pipe allows experimentation that is sensitive to moisture or other environment.

·A wide range of Vessel can be used from 250mlFlask to 25ml Tube.

·The upper part can be rotated 180 degrees, so it can be used in narrow spaces.

·High temperature and low temperature combined reactions are possible.

·Touch-screen monitors make it easy to use.

Model

|

DL-1002

|

DL-1004

|

| Heating block | 2ea | 4ea |

| Number of specimen | 250㎖ - 2ea / 25㎖ - 8ea | 250㎖ - 4ea / 25㎖ - 16ea |

| Temperature controller | Digital PID controller | |

| Temperature range | -25℃ to 250℃ | |

| Temperature accuracy | ±0.5℃ at 180℃ | |

| Temperature sensor | PT 100Ω | |

| Stirring speed | 150~1200 r/min. | |

| Outlet for cooling water | 1 set | |

| Outlet for gas(N2) | 1 set | |

| Cooling chiller & block | User option | |

| Heater | 2000W | 4000W |

| Power source | 220VAC 50/60Hz single phase | 220VAC 50/60Hz single phase |

| Dimension(Internal) | 500(W) × 500(D) × 600(H)mm | 1000(W) × 700(D) × 1000(H)mm |

Up to four nozzles can be installed.

- Independent control is possible to maximize productivity.

·Adjusting the amount of solution radiation, velocity, time of release, and distance of radiation by nozzle

It's possible.

·Web using positive/negative voltages unlike melting and wet/dry radiation

A form of microfiber can be manufactured.

·Multiple components of nanofiber can be manufactured.

·Wide rollers can be used to manufacture various sizes of fiber.

·It is possible to produce support for tissue regeneration by forming a three-dimensional structure.

·10.4 inch large touch PC installed to check work status in real time

It's possible.

|

||||||||||||||||||

본 사이트는

Internet Explorer 8 이하 버전을

지원하지 않습니다.

Internet Explorer 9 이상으로 업데이트 하거나

크롬, 파이어폭스, 오페라, 사파리 최신 브라우저를 이용해 주십시오.

불편을 드려 죄송합니다.