;Modify Date : 2020-07-28 16:59:21

monitoring system

During tapping, the load being converted is measured in real time to monitor for defective threads.

Analyze and predict the measured load to determine the wear condition, damage, replacement time, etc. of the TAP.

Improves productivity and product quality with immediate facility shutdown and alarm functions.

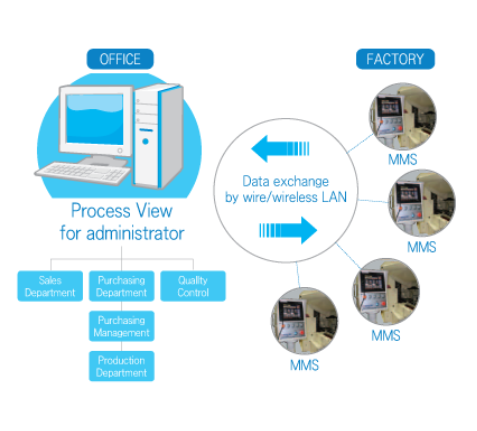

Effective Production Management

Real-time exchange of information between offices and sites

Identifying the processing status, production quantity, products, and equipment of each machine

Determine the condition of tab wear on each machine

Up to 240 unified management

tapping-only oil

Development of cutting and precursor oil suitable for processing characteristics and products

TAP Lifetime Improvement/Plastic Green Materials

본 사이트는

Internet Explorer 8 이하 버전을

지원하지 않습니다.

Internet Explorer 9 이상으로 업데이트 하거나

크롬, 파이어폭스, 오페라, 사파리 최신 브라우저를 이용해 주십시오.

불편을 드려 죄송합니다.