dehumidification systemModify Date : 2020-07-28 14:32:58

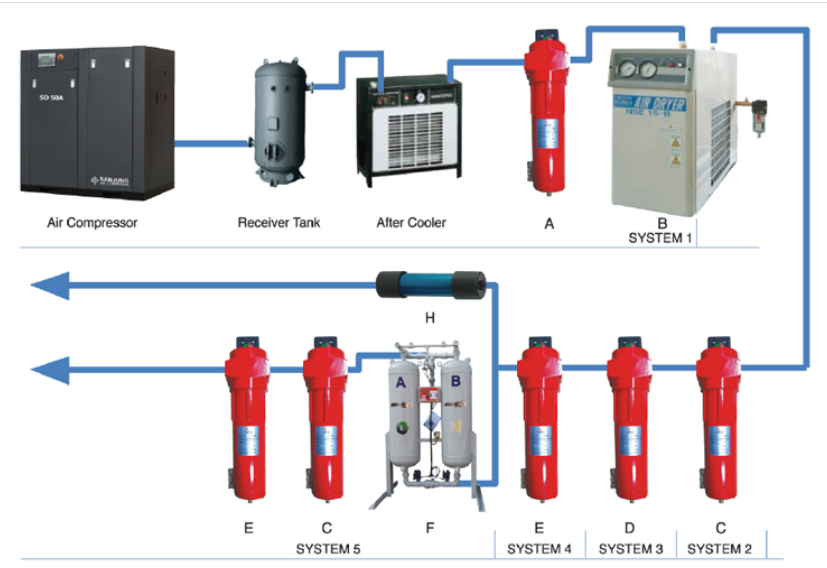

Air System

When the air in the atmosphere is inhaled by the compressor, the production line and the contaminants generated by the compressor are affected by the impurities inhaled from the outside.

As the life and function of various pneumatic devices of the compressor will affect productivity or quality, consideration of contamination of the pneumatic system should be given first.

After that, the proper air cleaning system should be selected considering the performance and characteristics of pneumatic devices and comprehensive review of economic feasibility, reliability, stability, and repair management.

| Description | A | B | C | D | E | F | H |

|---|---|---|---|---|---|---|---|

| Item | Main Filter | Reftigerant Air Dryer | Pre Filter | Line Filter | Coalescer Filter | Desiccant Air Dryer | Membrane Dryer |

| CLEANSING SYSTEM TABLE | ||

|---|---|---|

| SYSTEM 1 | A, B | General Pneumatic Line (Electronic Side, Air Cylinders) General in dustry Line (electronic q modulation, air cylinder) |

| SYSTEM 2 | A, B, C | pneumatic machinery, tools, general dryness Pnerumetic machine, tools, general dry |

| SYSTEM 3 | A, B, C, D | Automatic control line precision component drying line metering, painting, and instrumentation line Automatic control line, precision part drying line, measurement, sealing line |

| SYSTEM 4 | A, B, C, D, E | Hospital/medicine test, transport, stirring, drying Testing, transportaion, agitation, drying of hospital/medicine drugs |

| SYSTEM 5 | A, B, C, D, E, F, C, E | Semiconductor, electronic parts ultra-precision industry, robot chemical analysis device Semiconductior, electronic componnent hyper precision industry, robotic chemicalanalysis device |

SYSTEM 5 | A, B, C, D, E, H | Semiconductor, electronic parts ultra-precision industry, robot chemical analysis device precision industry, |

Desiccant Air Dryer

The products are energy-saving adsorption type air dryers which iseless than 1% of dry air, as the products operate by using minimum compressed air and reproduce adsorbents by using a blower after inhaling outside air, and thus adsorbents have linger lifespan due to less direct contact with heat by adsorbents.

| Model | Flow Capcity (N㎡/min) | In/Out Connect | Alumina | Heater | Blower | Dimensions(mm) | Weight (kg) | ||

|---|---|---|---|---|---|---|---|---|---|

| 2Tower(Kg) | (Kw) | (HP) | L | W | H | ||||

| PHB - 30 | 4.20 | 1"(S) | 138 | 4 | 2 | 1800 | 1200 | 2340 | 470 |

| PHB - 50 | 7.10 | 1-1/2"(S) | 189 | 5 | 2 | 1900 | 1250 | 2240 | 630 |

| PHB - 75 | 11.00 | 2"(S) | 230 | 7.5 | 3 | 2100 | 1350 | 2480 | 840 |

| PHB - 100 | 14.50 | 354 | 9 | 3 | 2200 | 1400 | 2460 | 1030 | |

| PHB - 125 | 17.50 | 2-1/2"(F) | 462 | 10.5 | 5 | 2400 | 1450 | 2580 | 1360 |

| PHB - 150 | 21.90 | 530 | 13.5 | 5 | 2500 | 1500 | 2600 | 1510 | |

| PHB - 200 | 32.50 | 3"(F) | 650 | 18 | 7.5 | 2700 | 1550 | 2640 | 1780 |

| PHB - 250 | 38.30 | 760 | 24 | 7.5 | 2800 | 1600 | 2610 | 2010 | |

| PHB - 300 | 49.50 | 4"(F) | 840 | 27 | 7.5 | 2900 | 1650 | 2630 | 2230 |

| PHB - 400 | 58.50 | 1130 | 30 | 7.5 | 3200 | 1750 | 2580 | 2730 | |

| PHB - 500 | 75.00 | 5"(F) | 1450 | 38 | 10 | 3200 | 1900 | 2980 | 3230 |

| PHB - 600 | 112.00 | 6"(F) | 1770 | 42 | 10 | 3300 | 1950 | 3050 | 3700 |

| PHB - 800 | 127.00 | 2030 | 46 | 15 | 3700 | 2100 | 2930 | 4580 | |

| PHB - 900 | 139.00 | 2280 | 60 | 15 | 3900 | 2300 | 3140 | 5600 | |

| PHB - 1000 | 145.00 | 8"(F) | 2835 | 72 | 20 | 4200 | 2500 | 3050 | 6700 |

| PHB - 1200 | 160.00 | 3790 | 90 | 20 | 4400 | 2600 | 3150 | 7600 | |

| PHB -1300 | 174.00 | 4100 | 120 | 30 | 4600 | 2800 | 3190 | 9400 | |

| PHB - 1500 | 200.00 | 4720 | 150 | 30 | 5200 | 3000 | 3200 | 11500 | |

| PHB - 1800 | 242.00 | 10"(F) | 5620 | 170 | 40 | 5800 | 3200 | 3190 | 1400 |

REMARKS

- We used activated alumina gel which has high mechanical strength and performance.

- The products generate high-quality compressed air with dew point temperature not higher than -40℃ due to its superior dehumidifyung effect.

- The products can smoothly convert flow of compressed air to the tower by using its self-developed shuttle valve.

- As a type of reproducing adsorbents by heater blower, the products can provide high-quality pure compressed air.

- The products are certified by the Korea Occupational Saftey & Agency.

- The above specification mat change without any prior notice for the purpose of quality improvement.

Desiccant Air Dryer

Notwithstanding the istalled dehumidifying equipment. If you use oil adsorption-type air dryer, because you need higher-quality clean compressed air or want to solve any problem caused by evaporated grease, you can solve various problems associated with greasy components.

| Model | Flow Capcity (N㎡/min) | In/Out Connect | Alumina | Cabon | Dimensions(mm) | Weight (kg) | ||

|---|---|---|---|---|---|---|---|---|

| 2Tower(kg) | 1Tower(kg) | L | W | H | ||||

| POM - 7 | 0.68 | 1/2"(S) | 15 | 7 | 1120 | 700 | 1600 | 375 |

| POM - 10 | 1.40 | 3/4"(S) | 25 | 12 | 1160 | 700 | 1745 | 126 |

| POM - 15 | 2.00 | 31 | 14 | 1320 | 700 | 1745 | 149 | |

| POM - 20 | 2.80 | 1"(s) | 60 | 25 | 1520 | 700 | 1745 | 180 |

| POM - 30 | 4.20 | 92 | 37 | 1545 | 800 | 1780 | 270 | |

| POM - 50 | 7.10 | 1-1/2"(S) | 138 | 60 | 1870 | 900 | 1870 | 375 |

| POM - 75 | 11.00 | 2"(S) | 189 | 77 | 1900 | 1000 | 1880 | 500 |

| POM - 100 | 14.50 | 230 | 95 | 2040 | 1000 | 1880 | 638 | |

| POM - 125 | 17.50 | 2-1/2"(F) | 354 | 150 | 2300 | 1000 | 2260 | 786 |

| POM - 150 | 21.90 | 462 | 190 | 2420 | 1000 | 2270 | ||

| POM - 200 | 32.50 | 3"(F) | 530 | 212 | 3070 | 1100 | 2450 | |

| POM - 250 | 38.30 | 650 | 265 | 3120 | 1100 | 2500 | ||

| POM - 300 | 49.50 | 4"(F) | 760 | 320 | 3210 | 1200 | 2550 | |

| POM - 400 | 53.50 | 840 | 360 | 3220 | 1250 | 2580 | ||

| POM - 500 | 66.67 | 5"(F) | 1130 | 505 | 3490 | 1300 | 2800 | |

| POM - 600 | 75.00 | 1450 | 660 | 3570 | 1350 | 3000 | ||

| POM - 800 | 83.33 | 6"(F) | 1770 | 815 | 3670 | 1400 | 3000 | |

| POM - 900 | 98.60 | 2030 | 940 | 3760 | 1400 | 3100 | ||

| POM - 1000 | 125.00 | 2280 | 1060 | 3850 | 1500 | 3250 | ||

| Model | Flow Capcity (N㎡/min) | In/Out Connect | Alumina | Heater | Dimensions(mm) | Weight (kg) | ||

|---|---|---|---|---|---|---|---|---|

| 2Tower(kg) | (㎾) | L | W | H | ||||

| PHP - 10 | 1.40 | 3/4"(S) | 31 | 2 | 1000 | 750 | 1745 | |

| PHP - 15 | 2.00 | 60 | 2 | 1150 | 750 | 1745 | ||

| PHP - 20 | 2.80 | 1"(s) | 92 | 3 | 1300 | 850 | 1780 | |

| PHP - 30 | 4.20 | 138 | 4 | 1400 | 1000 | 1870 | ||

| PHP - 50 | 7.10 | 1-1/2"(S) | 189 | 5 | 1450 | 1100 | 1880 | |

| PHP - 75 | 11.00 | 2"(S) | 230 | 7.5 | 1650 | 1200 | 1880 | |

| PHP - 100 | 14.50 | 354 | 9 | 1750 | 1200 | 2260 | ||

| PHP - 125 | 17.50 | 2-1/2"(S) | 462 | 10.5 | 1900 | 1300 | 2270 | |

| PHP - 150 | 21.90 | 530 | 13.5 | 2100 | 1400 | 2450 | ||

| PHP - 200 | 32.50 | 3"(S) | 650 | 18 | 2100 | 1400 | 2500 | |

| PHP - 250 | 38.30 | 760 | 24 | 2130 | 1500 | 2550 | ||

| PHP - 300 | 49.50 | 4"(S) | 840 | 27 | 2130 | 1500 | 2580 | |

| PHP - 400 | 53.50 | 1130 | 30 | 2250 | 1650 | 2800 | ||

| PHP - 500 | 66.67 | 5"(S) | 1450 | 38 | 2300 | 1650 | 3000 | |

| PHP - 600 | 75.00 | 1770 | 42 | 2300 | 1800 | 3000 | ||

| PHP - 800 | 83.33 | 6"(S) | 2030 | 46 | 2350 | 1800 | 3100 | |

| PHP - 900 | 98.60 | 2280 | 60 | 2350 | 1900 | 3250 | ||

| PHP - 1000 | 125.00 | 2835 | 72 | 2400 | 1900 | 3250 | ||

REMARKS

- We used activated alumina gel which has high mechanical strength and performance.

- The products generate high-quality compressed air with dew point temperature not higher than -40℃ due to its superior dehumidifyung effect.

- The products can smoothly convert flow of compressed air to the tower by using its self-developed shuttle valve.

- As a type of reproducing adsorbents by heater blower, they can provide high-quality pure compressed air.

- The products are certified by the Korea Occupational Saftey & Agency (starting from PAH-15).

- The above specification mat change without any prior notice for the purpose of quality improvement.

Desiccant Air Dryer

The products operate with the processes, where compressed

air flows into A-Tower and B-Tower alternately through the

shuttle valve, and any moisture contained in the compressed

air is removed while passing through adsorbents, and

condensate water adsorbed by adsorbents is compressed for

2 minutes, adsorbed fot 8 minutes, and reproduced. They

can be used economicallt as separate energy for reproduction

is not needed. It is a vasic model most widely used for

general purpose, for which repair of parts is easily made.

| Model | Flow Capcity (N㎡/min) | In/Out Connect | Alumina | Dimensions(mm) | Weight (kg) | ||

|---|---|---|---|---|---|---|---|

| 2Tower(kg) | L | W | H | ||||

| PAH - 5 | 0.57 | 1/2"(S) | 10 | 680 | 350 | 1135 | 56 |

| PAH - 7 | 0.68 | 15 | 720 | 700 | 1600 | 84 | |

| PAH - 10 | 1.40 | 3/4"(S) | 25 | 760 | 700 | 1745 | 99 |

| PAH - 15 | 2.00 | 31 | 770 | 700 | 1745 | 120 | |

| PAH - 20 | 2.80 | 1"(s) | 60 | 925 | 700 | 1745 | 182 |

| PAH - 30 | 4.20 | 92 | 1020 | 800 | 1780 | 250 | |

| PAH - 50 | 7.10 | 1-1/2"(S) | 138 | 1160 | 900 | 1870 | 333 |

| PAH - 75 | 11.00 | 2"(S) | 189 | 1260 | 1000 | 1880 | 425 |

| PAH - 100 | 14.50 | 230 | 1370 | 1000 | 1880 | 524 | |

| PAH - 125 | 17.50 | 2-1/2"F) | 354 | 1440 | 1000 | 2260 | |

| PAH - 150 | 21.90 | 462 | 1490 | 1100 | 2270 | ||

| PAH - 200 | 32.50 | 3"(F) | 530 | 2100 | 1100 | 2450 | |

| PAH - 250 | 38.30 | 650 | 2100 | 1200 | 2500 | ||

| PAH - 300 | 49.50 | 4"(F) | 760 | 2130 | 1250 | 2550 | |

| PAH - 400 | 53.50 | 840 | 2130 | 1300 | 2580 | ||

| PAH - 500 | 66.67 | 5"(F) | 1130 | 2250 | 1350 | 2800 | |

| PAH - 600 | 75.00 | 1450 | 2300 | 1350 | 3000 | ||

| PAH - 800 | 83.33 | 6"(F) | 1770 | 2300 | 1400 | 3000 | |

| PAH - 900 | 98.60 | 2030 | 2350 | 1400 | 3100 | ||

| PAH - 1000 | 125.00 | 2280 | 2350 | 1500 | 3250 | ||

| PAH - 1200 | 142.00 | 2835 | 2400 | 1500 | 3250 | ||