ceiling metal finishing materialModify Date : 2020-07-17 11:27:01

AL TILE SYSTEM General Aspects

(1) Terms definition

1 System : AL-TILE SYSTEM

2 Gong Act: CLIP-IN (TYPE inserts TILE into CLIP-BAR)

(2) Transportation and Handling

1 Transport: Delivery after packing by specifying the type, title, dimensions, date of manufacture, etc. on the label

2 Handling: Handle according to the manufacturer's instructions and the user's precautions.

AL TILE SYSTEM PRODUCT

(1) Material

1 Material quality: KSD 7081 (Architectural Colouring Metal Ceiling Material)

KSD 3609 (Forced Building Material)

(2) Specifications

1 HANGER BOLT: ψ9mm

2 HANGER & PIN: 105mm X 20mm X 2.0T

3 HANGER NUT: ψ9mm

4 CARRYING CHANNEL : 38mm X 12mm X 1.2T

5 C/C JOINT: 100 mm X 35 mm X 10 mm X 1.0T

6 MINOR CHANNEL : 19mm X 10mm X 1.2T

7 M/C CLIP: 38mm X 23mm X 14mm X 1.2T

STEEL TILE General Aspects

(1) Terms definition

1 System : AL-TILE SYSTEM

2 Gong Act: CLIP-IN (TYPE inserts TILE into CLIP-BAR)

(2) Transportation and Handling

1 Transport: Delivery after packing by specifying the type, title, dimensions, date of manufacture, etc. on the label

2 Handling: Handle according to the manufacturer's instructions and the user's precautions.

STEEL TILE PRODUCT

(1) Material

1 Material quality: KSD 7081 (Architectural Colouring Metal Ceiling Material)

KSD 3609 (Forced Building Material)

(2) Specifications

1 HANGER BOLT: ψ9mm

2 HANGER & PIN: 105mm X 20mm X 2.0T

3 HANGER NUT: ψ9mm

4 CARRYING CHANNEL : 38mm X 12mm X 1.2T

5 C/C JOINT: 100 mm X 35 mm X 10 mm X 1.0T

6 MINOR CHANNEL : 19mm X 10mm X 1.2T

7 M/C CLIP: 38mm X 23mm X 14mm X 1.2T

8 Shaped CLIP-BAR

9 Shaped CLIP-BAR CLIP

10 STEEL-TILE: Refer to the site drawings for TILE SIZE and TYPE.

STEEL TILE Features

* It is non-combustible ceiling material.

* It can be used in humid places such as swimming pools.

* Colors are beautiful and diverse.

* Sound effects are also excellent by adding sound absorbents to the pores and backside.

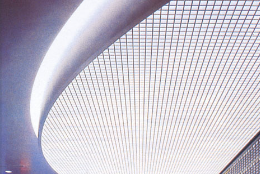

Overview of AL CANO TILE for Wind Resistance Pressure

The AL TILE system, which is the most commonly used metal finishing materials applied to the interior and exterior ceilings of buildings, adopted CLIP-IN-type fixation method, which raised the possibility of elimination when used in external canopy and filotiation, and caused elimination due to actual wind. The CANOTILE system developed by Yoo Chang has adopted SCREW fixing method to improve robustness, secure wind-resistant pressure performance, and form a 15mm or 20mm point line to ensure a beautiful appearance.

AL CANO TILE CONFIGURATION FOR Wind-resistant Pressure

(1) Material

Material quality: KSD 3506 (Helted galvanized steel plate)

KSD3609 (Forced Building Material)

(2) Specifications

1 SQ-BAR : 30X40X0.45T or higher

2 Wind-resistant ballT: 15mm (L=1,200 or less) or 20mm (1,600 or less)

3 HANGER & BEES : 32X160X2.0T

4 HANGER NUT : ψ9

5 SQ-BAR JOINT : 0.6T

6 SQ-BAR CLIP & BEES : 0.8T

7 SQ-RUNNER : 32x40x0.6T or higher

8 AL MAIN JOINER:Width = 15MM, L=3,690

9AL CROSS JOINER & CLIP:Width=15MM, L=600

10AL CANO-TILE: 615X615X0.7T or higher,

11 MOLDING: 37X18X1.0T

12 SUS Fixed Clips

General AL CANO TILE (M-BAR) Overview

The AL TILE system, which is the most commonly used metal finishing materials applied to the interior and exterior ceilings of buildings, adopted CLIP-IN-type fixation method, which raised the possibility of elimination when used in external canopy and filotiation, and caused elimination due to actual wind. The CANOTILE system developed by Yoo Chang has adopted SCREW fixing method to improve robustness, secure wind-resistant pressure performance, and form a 15mm or 20mm point line to ensure a beautiful appearance.

General AL CANO TILE (M-BAR) configuration

(1) Material

Material quality: KSD 3506 (Helted galvanized steel plate)

KSD 3609 (Forced Building Material)

(2) Specifications

1 M-BAR: 50mm X 19mm X 0.5T

2 HANGER BOLT: ψ9mm

3 HANGER & PIN: 100mm X20mm X 2.0T

4 HANGER NUT: ψ9mm

5 CARRYING CHANNEL : 38mm X12mm X 1.2T

6 C/CJOINT: 100mm X 35mm X 10mm X 1.0T

7 MINORCHANNEL : 19mm X 10mm X 1.2T

8 M/C CLIP: 38mm X 23mm X 14mm X 1.2T

9 M-BAR CLIP: 38mm X 47mm X 0.5T

10 M-BAR JOINT: 85mm x 47mm x0.5T

11 AL MAIN JOINER: Width=20MMM, 15MM, L=3,000

12 AL CROSS JOINER & CLIP: Width=20MMM, 15MM,L=600

STEEL TILE (LINE T-BAR) 600*600 General Aspects

(1) Terms definition

1 System : STEEL-TILE SYSTEM

2 Gong Act: LAY-ON (TYPE with TILE on LINE T-BAR)

(2) Transportation and Handling

1 Transport: Delivery after packing by specifying the type, title, dimensions, date of manufacture, etc. on the label

2 Cooking: Handle according to the manufacturer's instructions and the user's precautions.

STEEL TILE (LINE T-BAR) 600*600 Products

1) Material

1 Material quality: KSD 7081 (Architectural Colouring Metal Ceiling Material)

KSD 3609 (Forced Building Material)

(2) Specifications

1 HANGER BOLT: ψ9mm

2 HANGER & PIN: 105mm X 20mm X 2.0T

3 HANGER NUT: ψ9mm

4 CARRYING CHANNEL : 38mm X 12mm X 1.2T

5 C/C JOINT: 100mm X 35mm X 10mm X 1.0T

6 MINOR CHANNEL : 19mm X 10mm X 1.2T

7 M/C CLIP: 38mm X 23mm X 14mm X 1.2T

8 MAIN LINE T-BAR ; 15mm X 42mm X 0.5T

9 CROSS LINE T BAR ; 15mm X 42mm X 0.5T

10 STEEL-TILE: Refer to the site drawings for TILE SIZE and TYPE.

STEEL TILE (LINE T-BAR) 600*600 Features

* It is non-combustible ceiling material.

* It can be used in humid places such as swimming pools.

* Colors are beautiful and diverse.

* Colouring zinc is also light and strong with steel plates.

* Sound effects are also excellent by adding sound absorbents to the pores and backside.

* Medium-sized modules are suitable for narrow spaces.

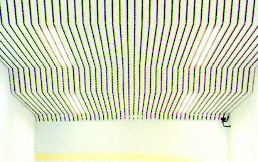

AL TILE (100 bar) SYSTEM General Aspects

(1) Terms definition

1 System : AL 100BAR SYSTEM

2 Gong Act: PUT-IN PANEL SYSTEM (TYPE fitted with plate CLIP)

(2) Transportation and Handling

1 Transport: Delivery after packing by specifying the type, title, dimensions, date of manufacture, etc. on the label

2 Handling: Handle according to the manufacturer's instructions and the user's precautions.

AL TILE (100 bar) SYSTEM PRODUCT

(1) Material

1 Material quality: KSD 7081 (Architectural Colouring Metal Ceiling Material)

KSD 3609 (Forced Building Material)

(2) Specifications

1 HANGER BOLT: 9mm X 1,000

2 HANGER & PIN: 150X30X2.0T

3 HANGER NUT : ψ9

4 CARRYING CHANNEL : 63X25X1.6T

5 MINOR CHANNEL : 19X10X1.2T

6 M/C CLIP : 38X23X14X1.2T

7 AL100BAR : 100X44X1.2T (W=100)

8 AL 50BAR : 50X44X1.2T (W=50)

9 BAR JOINT: 100X29X1.2T (W=100), 100X40X1.2T (W=50)

10 BAR CLIP : W=100, W=50

11 AL PANEL : Installation by SIZE (see design drawing)

AL TILE (100 bar) SYSTEM Features

* It is non-combustible ceiling material.

* It can be used in humid places such as swimming pools.

* Colors are beautiful and diverse.

* The material is light with aluminum.

* Sound effects are also excellent by adding sound absorbents to the pores and backside.

* Large modules are suitable for large spaces such as subways.

S-TYPE AL 100S General Aspects

(1) Terms definition

1 System : SPANDREL (100S) SYSTEM

2 Gong Act: Fix SPANDREL on M-BAR (M-BAR) with a piece and use SPANDREL and SPANDREL.

TYPE for construction by insertion)

(2) Transportation and Handling

1 Transport: Delivery after packing by specifying the type, title, dimensions, date of manufacture, etc. on the label

2 Handling: Handling according to the manufacturer's instructions and the user's precautions

S-TYPE AL 100S Product

(1) Material

1 Material quality: KSD 7081 (Architectural Colouring Metal Ceiling Material)

KSD 3609 (Forced Building Material)

(2) Specifications

1 HANGER BOLT: ψ9mm

2 HANGER & PIN: 105mm X 20mm X 2.0T

3 HANGER NUT: ψ9mm

4 CARRYING CHANNEL : 38mm X 12mm X 1.2T

5 C/C JOINT: 100mm X 35mm X 10mm X 1.0T

6 MINOR CHANNEL : 19mm X 10mm X 1.2T

7 M/C CLIP: 38mm X 23mm X 14mm X 1.2T

8 M-BAR: 50mm X 19mm X 0.5T

9 M-BAR CLIP : 38mm X 47mm X 0.5T (for M-BAR)

10 M-BAR JOINT: 100mm X 43mm X 0.5T (for M-BAR)

11 SPANDREL (100S): 0.5T

12 MOLDING

S-TYPE AL 100S Features

* It is non-combustible ceiling material.

* It can be used in humid places such as swimming pools.

* Colors are beautiful and diverse.

* The material is light with aluminum.

* Sound effects are also excellent by adding sound absorbents to the pores and backside.

* Strong against wind pressure and moisture, suitable for external canopy lamps.

S-TYPE AL 250S General Aspects

(1) Terms definition

1 System : SPANDREL (250S) SYSTEM

2 Gong Act: Fix SPANDREL on M-BAR (M-BAR) with a piece and use SPANDREL and SPANDREL.

TYPE for construction by insertion)

(2) Transportation and Handling

1 Transport: Delivery after packing by specifying the type, title, dimensions, date of manufacture, etc. on the label

2 Handling: Handling according to the manufacturer's instructions and the user's precautions

S-TYPE AL 250S Product

(1) Material

1 Material quality: KSD 7081 (Architectural Colouring Metal Ceiling Material)

KSD 3609 (Forced Building Material)

(2) Specifications

1 HANGER BOLT: ψ9mm

2 HANGER & PIN: 105mm X 20mm X 2.0T

3 HANGER NUT: ψ9mm

4 CARRYING CHANNEL : 38mm X 12mm X 1.2T

5 C/C JOINT: 100mm X 35mm X 10mm X 1.0T

6 MINOR CHANNEL : 19mm X 10mm X 1.2T

7 M/C CLIP: 38mm X 23mm X 14mm X 1.2T

8 M-BAR: 50mm X 19mm X 0.5T

9 M-BAR CLIP : 38mm X 47mm X 0.5T (for M-BAR)

10 M-BAR JOINT: 100mm X 43mm X 0.5T (for M-BAR)

11 SPANDREL (250S): 0.5T

12 MOLDING

S-TYPE AL 250S Construction Method

* It is non-combustible ceiling material.

* It can be used in humid places such as swimming pools.

* Colors are beautiful and diverse.

* The material is light with aluminum.

* Sound effects are also excellent by adding sound absorbents to the pores and backside.

* Strong against wind pressure and moisture, suitable for external canopy lamps.

AL SPANDREL CANO 26S CONFIGURATION

(1) Material

Material quality: KSD 3506 (Helted galvanized steel plate)

KSD 3609 (Forced Building Material)

(2) Specifications

1 M-BAR: 50mm X 19mm X 0.5T

2 HANGER BOLT: ψ9mm

3 HANGER & PIN: 100mm X 20mm X 2.0T

4 HANGER NUT: ψ9mm

5 CARRYING CHANNEL : 38mm X 12mm X 1.2T

6 C/C JOINT: 100mm X 35mm X 10mm X 1.0T

7 MINOR CHANNEL : 19mm X 10mm X 1.2T

8 M/C CLIP: 38mm X 23mm X 14mm X 1.2T

9 M-BAR CLIP: 38mm X 47mm X 0.5T

10 M-BAR JOINT: 85mm x 47mm x 0.5T

11 AL MAIN JOINER: Width=20MMM, 15MM, L=3,000

12 AL CROSS JOINER & CLIP: Width=20MMM, 15MM, L=600

13 AL SPANDREL (CANO-26S): 0.5T,

14 MOLDING: 37X18X1.0T

15 SUS Fixed Clips

AL SPANDREL 300S WAVE General Aspects

(1) Terms definition

1 System : SPANDREL (300S WAVE) SYSTEM

2 Gong Act: Fix SPANDREL on M-BAR (M-BAR) with a piece and use SPANDREL and SPANDREL.

TYPE for construction by insertion)

(2) Transportation and Handling

1 Transport: Delivery after packing by specifying the type, title, dimensions, date of manufacture, etc. on the label

2 Handling: Handling according to the manufacturer's instructions and the user's precautions

AL SPANDREL 300S WAVE PRODUCT

(1) Material

1 Material quality: KSD 7081 (Architectural Colouring Metal Ceiling Material)

KSD 3609 (Forced Building Material)

2 PAINTING SPANDREL OF METAL Ceiling Plate: KSD 9502 (REFERENCE TEST) PROTECTIONS

KSM 5435 (Coating Thickness Curve Test)

3 Surface condition and color

Go. The colouring of the surface shall be clean and smooth.

Me There shall be no peeling of any colorant or spot or pigment on the surface.

Everything. The surface conditions around the holes shall be smooth and smooth. (Applies to the plate)

La The collar is subject to separate designation.

4 Absorption Performance

KSF 2805 (residual test) and specifications of the manufacturer. (Applies to the plate)

(2) Specifications

1 HANGER BOLT: ψ9mm

2 HANGER & PIN: 105X20X2.0T

3 HANGER NUT: ψ9mm

4 CARRYING CHANNEL : 38X12X1.2T

5 C/C JOINT: 100X35X10X1.0T

6 MINOR CHANNEL : 19X10X1.2T

7 M/C CLIP : 38X23X14X1.2T

8 M-BAR : 50X19X0.5T

9 M-BAR CLIP : 0.6T (for M-BAR)

10 M-BAR JOINT: 0.5T (for M-BAR)

11 AL-SPANDREL (300S WAVE): 1.0T

12 MOLDING: Angle or gull moulding

Construction Method of AL SPANDREL 300S WAVE

* It is non-combustible ceiling material.

* It can be used in humid places such as swimming pools.

* Colors are beautiful and diverse.

* The material is light with aluminum.

* Sound effects are also excellent by adding sound absorbents to the pores and backside.

* Strong against wind pressure and moisture, suitable for external canopy lamps.

SPANDREL T-PANEL General Aspects

(1) Terms definition

1 System : SPANDREL (T-PANNEL) SYSTEM

2 Gong Act: Fix SPANDREL on M-BAR (M-BAR) with a piece and use SPANDREL and SPANDREL.

TYPE for construction by insertion)

(2) Transportation and Handling

1 Transport: Delivery after packing by specifying the type, title, dimensions, date of manufacture, etc. on the label

2 Handling: Handling according to the manufacturer's instructions and the user's precautions

SPANDREL T-PANEL PRODUCT

(1) Material

1 Material quality: KSD 7081 (Architectural Colouring Metal Ceiling Material)

KSD 3609 (Forced Building Material)

(2) Specifications

1 HANGER BOLT: ψ9mm

2 HANGER & PIN: 105mm X 20mm X 2.0T

3 HANGER NUT: ψ9mm

4 CARRYING CHANNEL : 38mm X 12mm X 1.2T

5 C/C JOINT: 100mm X 35mm X 10mm X 1.0T

6 MINOR CHANNEL : 19mm X 10mm X 1.2T

7 M/C CLIP: 38mm X 23mm X 14mm X 1.2T

8 M-BAR: 50mm X 19mm X 0.5T

9 M-BAR CLIP : 38mm X 47mm X 0.5T (for M-BAR)

10 M-BAR JOINT: 100mm X 43mm X 0.5T (for M-BAR)

11 SPANDREL (T-PANNEL): 0.5T

12 MOLDING

SPANDREL T-PANEL Features

* It is non-combustible ceiling material.

* It can be used in humid places such as swimming pools.

* Colors are beautiful and diverse.

* The material is light with aluminum.

* Strong against wind pressure and moisture, suitable for external canopy lamps.

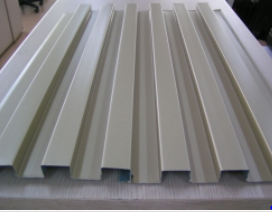

PLANK TYPE INVESTIONS

The PLANK is available in a variety of specifications, freeing up LAYOUT, which requires the installation of partitions, as well as effective module design. The PLANK, which adopts general porous products for the indoor environment of the centrally managed OFFICE building and provides the best finish, is a SYSTEM ceiling that provides optimal architectural environmental factors such as sound, comfort, DESIGN, and facilities, and is suitable for intelligent buildings, airport waiting rooms, and conference rooms.

PLANK TYPE Products

(1) Material

1 Material quality: KSD 3506 (Helted galvanized steel plate)

KSD 3520 (Coating Coated Zinc Plates)

KSD 3609 (Forced Support Material for Building)

2 Color: White (internal: black or white) is the standard, and other colors are agreed upon.

3 Surface treatment: Polyester resin coating (20 micron or higher)

(2) Specifications

1 MAIN MODULE T-BAR: 70mm X 38mm X 0.8T

2 CROSS MODULE T-BAR: 70mm X 38mm X 0.8T

3 HANGER BOLT: ψ9mm

4 HANGER & PIN: 105mm X 20mm X 2.0T

5 CARRYING CHANNEL : 38mm X 12mm X 1.2T

6 C/C JOINT: 100mm X 35mm X 10mm X 1.0T

7 C/T CLIP (for LINE T-BAR)

8 MINOR CHANNEL : 19mm X 10mm X 1.2T

9 M/C CLIP: 38mm X 23mm X 14mm X 1.2T

10 HANGER NUT: ψ9mm

11 GRID ; 100, 150, 200, 250, 300, length ; 3600.

PLANK TYPE Features

* Available in any shape, depending on the design of the ceiling.

* Various configurations are possible depending on the array.

* Suitable for advanced architecture such as intelligent buildings.

* Acoustic control is possible.

AL- LOUVER 15 General Aspects

(1) Terms definition

System : LOUVER SYSTEM

(2) Transportation and Handling

1 Transport: Delivery after packing by specifying the type, title, dimensions, date of manufacture, etc. on the label

2 Handling: Handling according to the manufacturer's instructions and the user's precautions

AL- LOUVER 15-angle product

(1) Material

1 Material quality: KSD 7081 (Architectural Colouring Metal Ceiling Material)

KSD 3609 (Forced Building Material)

(2) Specifications

1 ST'L MAIN T-BAR : 25X38X0.4T

2 ST'L CROSS T-BAR : 25X25X0.4T

3 HANGER BOLT: 9mm X 1,000

4 HANGER & PIN: 105X20X2.0T

5 CARRYING CHANNEL : 38X12X1.2T

6 C/C JOINT: 100X35X10X1.0T

7 C/T CLIP (for ST'L T-BAR)

8 MINOR CHANNEL : 19X10X1.2T

9 M/C CLIP : 38X23X14X1.2T

10 MOLDING

11 LOUVER: 600 Modules, 900 Modules, 600mm X 1200mm Modules

(15mm X 15mm X 15mm X 0.6T )

AL- LOUVER 15-angle feature

* Indirect lighting indicates a subtle atmosphere.

* Makes the giant structure look simple.

* Highlight the scalability of the floor height.

* It is suitable for subway and department stores by controlling noise.

AL- LOUVER 75 General Aspects

(1) Terms definition

System : LOUVER SYSTEM

(2) Transportation and Handling

1 Transport after packing by specifying the type, title, dimensions, date of manufacture, etc. on the label

2 Handling: Handling according to the manufacturer's instructions and the user's precautions

AL- LOUVER 75 Piece Products

(1) Material

1 Material quality: KSD 7081 (Architectural Colouring Metal Ceiling Material)

KSD 3609 (Forced Building Material)

(2) Specifications

1 ᄇ-BAR ; 42mm X 10mm x 1.2T

2 HANGER BOLT: ψ9mm

3 HANGER (for ᄇ-BAR)

4 HANGER NUT: ψ9mm

5 ᄇ-BAR JOINT

6 MOLDING

7 LOUVER : See the design drawing for SIZE.

(75mm X 75mm X 50mm X 10mm X 0.5T )

AL- LOUVER 75 Angle Features

* Indirect lighting indicates a subtle atmosphere.

* Makes the giant structure look simple.

* Highlight the scalability of the floor height.

* It is suitable for subway and department stores by controlling noise.

Design OPEN PANEL (AL, STEEL)

OPEN PANEL (AL, STEEL, non-combustion) OVERVIEW

Open panel, a system that dramatically improves structural instability, difficulty in maintaining/repairing the adhesion method, apparent problems caused by exposure to fixed screws, and lack of seismic function in preparation for continuous vibration, which is a problem with HANGER's established metal ceiling finishes, is capable of applying functional excellence, ease of construction, various designs, and thus canopy of office, commercial buildings, canopy of residential buildings, railway/loads.

OPEN PANEL (AL, STEEL, non-combustion) CONSTRUCTIONS FOR TRAINES

(1) Material

Material quality: KSD 3506 (Helted galvanized steel plate)

KSD 3609 (Forced Building Material)

(2) Specifications

1 ST'LMAIN T-BAR : 25X38X0.4T (L=3600)

2 ST'LCROSS T-BAR : 25X25X0.4T

3 HANGER BOLT: 9mm X 1,000

4 HANGER & PIN: 105X20X2.0T

5 CARRYING CHANNEL : 38X12X1.2T

6 C/C JOINT: 100X35X10X1.0T

7 C/TCLIP (for ST'L T-BAR)

8 MINOR CHANNEL : 19X10X1.2T

9 M/C CLIP : 38X23X14X1.2T

10HANGER NUT: ψ9

11MOLDING (for T-BARs for Open Panels)

12 Open Panel: 590X1190x0.8T

OPEN PANEL (AL, STEEL, non-combustion) features for subways

* SCREW is not visible and looks beautiful

* Excellent vibration and vibration tolerance

* Individual masks can be attached and do not need to be checked out

* Various plan configurations are possible.

AL TORSION PANEL OVERVIEW

The torsion panel, which adopts the vertical elastic force fixing method, is designed to easily detach and have strong seismic resistance to vibration such as earthquakes. It is easy to secure safety by preventing safety accidents such as injury by solving the problems of breakage of joints and elimination of metal finish panels by left and right/down vibrations. Therefore, it is easy to secure safety in the lobby of multi-public facilities such as commercial/residential/terrain, etc.

AL TORSION PANEL (Plate, Slope, Down) Configuration

(1) Material

Material quality: KSD 3506 (Helted galvanized steel plate)

KSD 3609 (Forced Building Material)

(2) Specifications

AL TORSION PANEL Features

* Open joint formation without screw (beautiful)

* Secures upper/lower/left-right seismic function

* Each panel can be detached and attached: Securing inspection function

* Sticking to T-BAR SYSTEM, a universal lightweight paper

AL SCREEN-BAR (CARRIER 33)

AL SCREEN-BAR (CARRIER 55)

AL SCREEN-BAR (External use, Peace fixed)

waterproof ceiling

Six patents, one utility model, four design registrations, PCT registration, U.S./Japan/China patent registration, India/EU patent application, and products and construction methods to prevent secondary damage, including loss of information resources due to damage to equipment and equipment caused by upper leakage of basic equipment, electric and medical equipment rooms, etc., to more safely manage information, which is a major resource in the information society from unforeseen accidents

본 사이트는

Internet Explorer 8 이하 버전을

지원하지 않습니다.

Internet Explorer 9 이상으로 업데이트 하거나

크롬, 파이어폭스, 오페라, 사파리 최신 브라우저를 이용해 주십시오.

불편을 드려 죄송합니다.