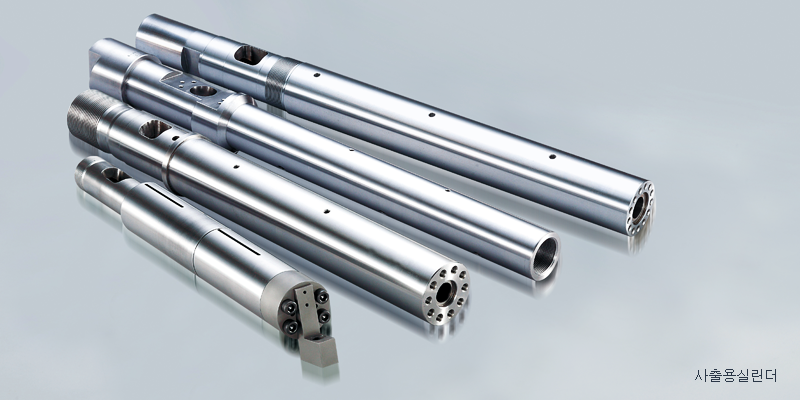

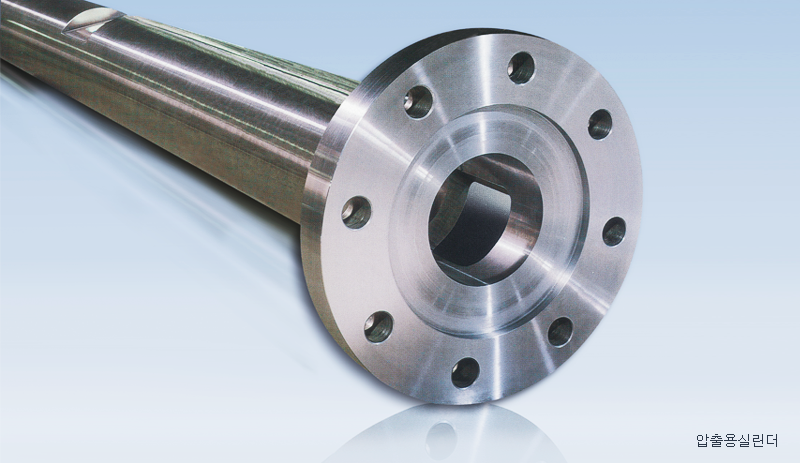

Injection / Extrusion CylinderModify Date : 2018-11-22 15:08:51

▣ Injection / Extrusion Cylinder

CYLINDER Overview

As a heating device, thermal stability (cylinder thickness) is required to maintain a constant melting temperature. In addition, precise straightness (+0.02) should be maintained to prevent unnecessary frictional heat during screw rotation.

Cylinder wear

Abrasion is mainly caused by abrasion and corrosion generated at the leading end (4D) where the screw head flows, and abrasion caused by friction generated at the resin inlet (first 5D) during weighing.

Allowable wear

Low Viscosity Resin -0.1mm, High Viscosity Resin -0.2mm

Cylinder selection

Recently, in order to improve the physical properties of resins, various resins such as reinforced plastic resins and super-enpra resins, in which glass fiber or Fila is added to resins, have been developed. The cylinder of the material should be selected and used.

Classification by material

material | material | material | |

Cylinder | SACM645 | Normal | General purpose resin |

ALLOY(Fe-Base) | High wear resistance | Abrasion Resistant (GF 10%) | |

ALLOY(Ni-Base) | Wear resistant, corrosion resistant | Corrosion and wear resistance (GF 30%) | |

ALLOY(W-Base) | Ultra wear resistance, corrosion resistant | Special specification |

본 사이트는

Internet Explorer 8 이하 버전을

지원하지 않습니다.

Internet Explorer 9 이상으로 업데이트 하거나

크롬, 파이어폭스, 오페라, 사파리 최신 브라우저를 이용해 주십시오.

불편을 드려 죄송합니다.