Injection ScrewModify Date : 2018-11-22 15:08:51

▣ Injection Screw

Injection Screw Overview

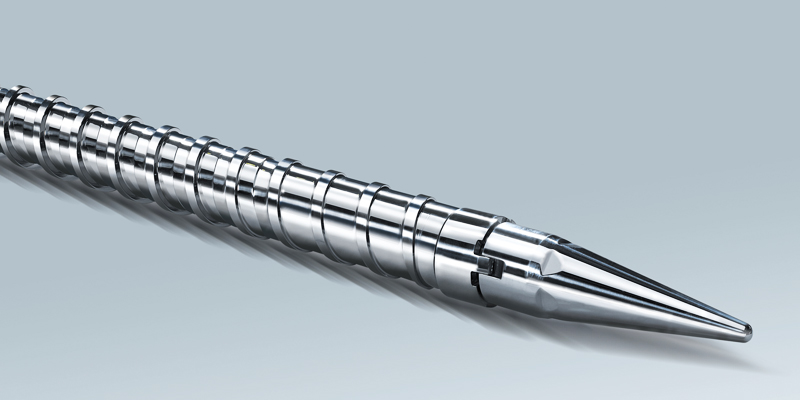

The role of the plasticizers SCREW & CYLINDER, the most important part of injection molding, is to supply homogeneous molten materials by thermally and mechanically changing the resin from a solid state to a fluid. The most important factors affecting the quality in this process are the selection of materials suitable for various resins, mechanical design and injection molding conditions (melting temperature, weighing, speed, back pressure, packing pressure).

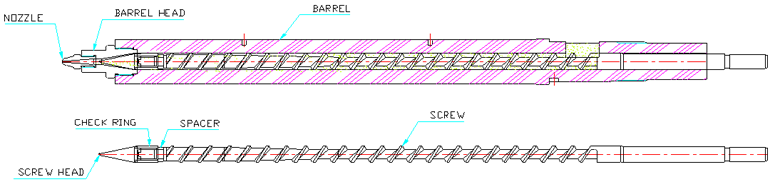

Screw Names and Roles

Screw design The screw design greatly changes the kneading state and plasticization capacity of the material, so that a design suitable for the physical properties of the resin is required.

Theoretical injection Maximum weight of molten material that is actually injected in one injection. Injection amount (g) = theoretical injection volume (cm 2) x density of molten material (g / cm 2) V = πⅮ² ÷ 4 × S × L (V: theoretical injection volume / D: screw diameter / S: specific gravity / L: stroke) Optimal screw diameter If the metering stroke is too small or too large for the screw diameter, thermal problems or surface defects can occur. Therefore, it is important to select the screw diameter suitable for the proper injection amount. Appropriate injection quantities are suitably formed at 1 to 3D metering strokes (min 0.8D, max 3.5D) of screw diameter. The resin residence time in the barrel should also be formed within an average of 4 minutes. Smaller diameter screws have higher injection pressure but lower theoretical injection volume and injection rate, while larger diameter screws have lower injection pressure, but higher theoretical injection volume and injection rate. Disadvantages when weighing stroke is smaller than screw diameter (within 1D) Provides a long residence time for thermally sensitive plastics. It takes a relatively long reaction time and a deviation of the reaction time of the non-return valve occurs. Difficult to speed up injection Disadvantages when weighing stroke is 3 times more than screw diameter (within 3D) Joules are caused by materials that are not completely melted. Bubbles are generated. Thermally uneven melt. Cause analysis for screw cylinder damage Material structure (low price, high performance) 25% Structure (compression, diameter) and design 8% Plastic Resin (Additive, Flame Retardant, Corrosive) 25% Usage (cycle time) 20% Molding condition (revolution back pressure temperature) 20% Maintenance 2% 02 classification by material Recently, in order to improve the physical properties of resins, various resins, such as so-called reinforced plastic resins and super-enpra resins, in which glass fibers or fillers are added to the resins, have been developed. The screw of the material should be selected and used.

03 SCREW Shape Classification In the ordinary full flight screw, the resin in the groove is only a simple kneading, so to obtain a sufficient kneading effect, the screw compression ratio must be increased, but this causes a decrease in plasticization capacity. Increasing kneading and plasticizing capacity are opposite conditions in screw geometry. In order to solve this problem, the high kneading screw was developed by changing the flight shape to give good pigment dispersion and uniformity of melting temperature.

|

본 사이트는

Internet Explorer 8 이하 버전을

지원하지 않습니다.

Internet Explorer 9 이상으로 업데이트 하거나

크롬, 파이어폭스, 오페라, 사파리 최신 브라우저를 이용해 주십시오.

불편을 드려 죄송합니다.